CB/T497-1994 Ballast Fire Protection System Sea water Filter -Coarse Water Filter AS300

Product Description

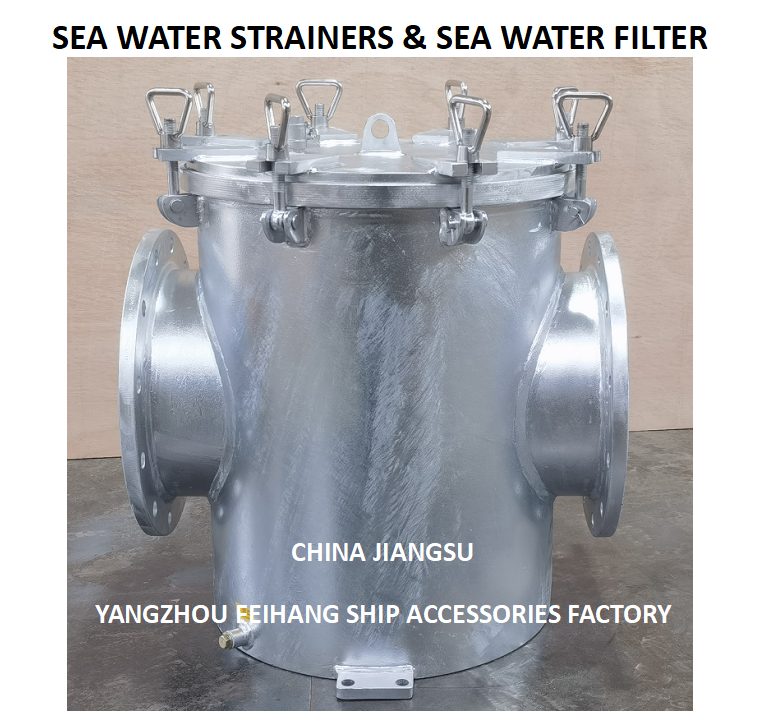

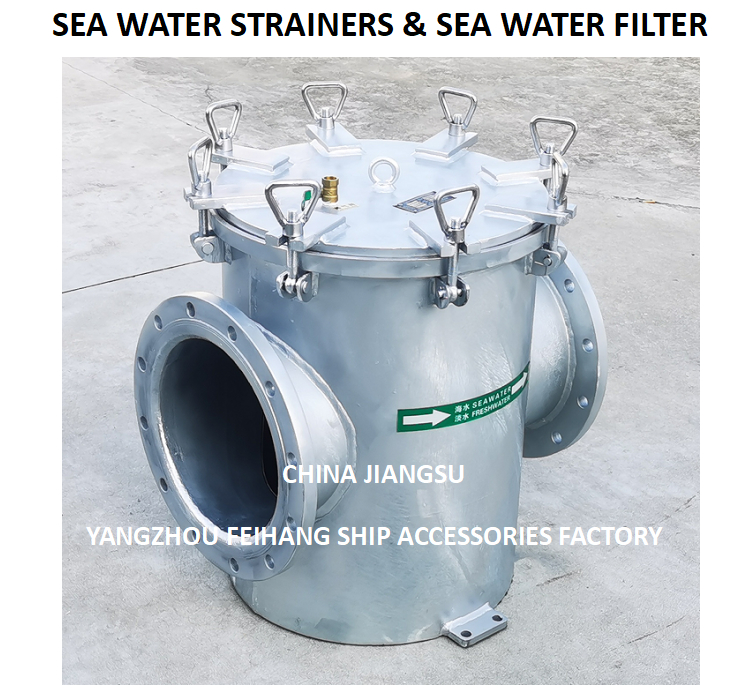

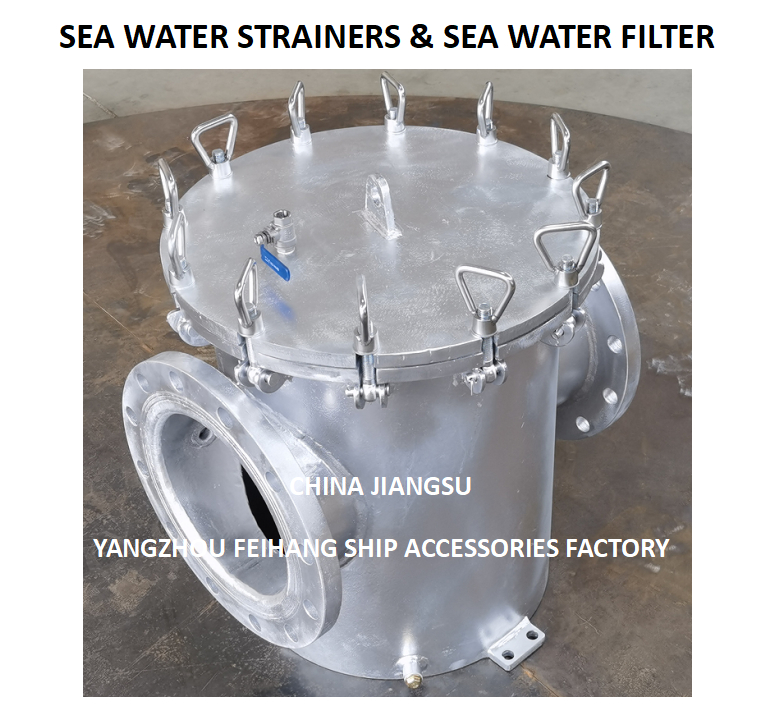

WATER FILTERS-SEA WATER FILTERS-SEA WATER STRAINERS

Implement standard CB/T497-2012

This standard is applicable to the design, manufacturing, and acceptance of filters for marine seawater and freshwater pipeline systems.

This standard (CB/T497-2012) specifies the classification, requirements, test methods, inspection rules, labeling, and packaging of suction coarse water filters (hereinafter referred to as seawater filters) with flange connection dimensions and sealing surfaces in accordance with GB/T569 and GB/T 2501 or other.

Marine Seawater Filter

Marine steel plate seawater filter can be equipped with either bolt or quick release hinge bolt cover unit, making it highly adaptable for various applications. The marine seawater filter manufactured by Yangzhou Aviation Ship Accessories Factory is designed for easy maintenance - simply open the cover plate and remove the filter element for cleaning.

Types of Marine Seawater Filters

- Type A - Flange connection size and sealing surface according to GB/T569 straight through suction coarse water filter seawater filter

- AS type - flange connection size and sealing surface according to GB/T2501 straight through suction coarse water filter - seawater filter

- BR type - flange connection size and sealing surface according to GB/T569 right angle suction coarse water filter seawater filter

- BRS type - flange connection size and sealing surface according to GB/T 2501 right angle suction coarse water filter - seawater filter

- BL type - flange connection size and sealing surface according to GB/T569 left angle suction coarse water filter - seawater filter

- BLS type - flange connection size and sealing surface according to GB/T2501 left angle suction coarse water filter - seawater filter

Product Features

- Product Name: Marine Sea Water Strainer

- Fillers: Nitrile Rubber, EPDM Rubber, PTFE, Fluororubber, Etc.

- Design Standards: CB/T497-2012

- Set up at the cover plate: Exhaust Valve

- Set up at the bottom: Discharge Port

- Filter Mesh: 1-10mm

Technical Parameters

| WORKING PRESSURE |

0.5Mpa - 1.0Mpa |

| SURFACE TREATMENT |

Hot Dip Galvanizing & Epoxy Coating |

| Application |

Seawater, Freshwater |

| Filter Mesh |

1-10mm |

| Set up at the cover plate |

Exhaust Valve |

| Median function |

Water |

| Body Material |

Carbon Steel & Stainless Steel |

| Connection Type |

Flanged |

| Set up at the bottom |

Discharge Port |

| SHAP |

ANGLE TYPE & Straight Through |

Applications

The FEIHANG L-TYPE(ANGLE TYPE) Marine Sea Water Strainer is a crucial component for various marine applications that involve the filtration of seawater and freshwater. Its high-quality design and construction make it ideal for use in demanding marine environments.

Designed and manufactured in Yangzhou, Jiangsu, China, this Marine Sea Water Strainer is certified with factory certificate, test report, and material report, ensuring its reliability and performance. The product complies with design standards CB/T497-2012, guaranteeing its quality and adherence to industry specifications.

Production Process

The marine seawater filters produced by Yangzhou Aviation Ship Accessories Factory strictly follow each production process, which includes carefully selecting raw materials, then rolling them through a plate rolling machine to form the seawater filter body, followed by welding connections, flanges, and welding connections between the filter body, connections, and flanges to form a preliminary shape. The filter cartridge is then customized according to customer requirements and finally assembled.

Testing Process

Each marine seawater filter produced by Yangzhou Aviation Ship Accessories Factory has undergone strict inspection and testing, and a test certificate is provided upon delivery.

After the assembly of the seawater filter is completed, a hydrostatic test shall be conducted with a test pressure of 1.5 times the working pressure for 5 minutes without leakage.

Corrosion Prevention

According to different customer requirements, the interior of this marine coarse water filter - marine seawater filter can be selected from: epoxy paint coating, hot-dip galvanizing treatment, spray coating treatment, rubber lining treatment.

According to different customer requirements, this marine coarse water filter - marine seawater filter surface can choose from: epoxy paint coating, hot-dip galvanizing treatment.

Packing and Shipping

The SEA WATER FILTER & SEA WATER STRAINERS is safely packaged in an export wooden box, designed to protect it during transportation. The box is clearly labeled with the product name and any relevant handling instructions. Then use a reliable transportation company to deliver it to the customer.

We are a qualified manufacturer (SEA WATER FILTER & SEA WATER STRAINERS) in China, and our products have been exported to customers around the world, such as Singapore, Dubai, Hamburg, United Arab Emirates, Netherlands, South Korea, Mexico, Thailand, Indonesia, Vietnam, Philippines, United Kingdom, etc.

Customer Deliveries

Frequently Asked Questions

Q: What is the brand name of this Marine Sea Water Strainer?

A: The brand name is FEIHANG.

Q: What is the model number of this Marine Sea Water Strainer?

A: The model number is L-TYPE (ANGLE TYPE).

Q: Where is this Marine Sea Water Strainer manufactured?

A: It is manufactured in Yangzhou, Jiangsu, China.

Q: What certifications does this Marine Sea Water Strainer have?

A: It comes with a Factory certificate, test report, and material report.

Q: What is the minimum order quantity for this Marine Sea Water Strainer?

A: The minimum order quantity is 1 piece.

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!